Laser welding

Perfect welds in hard-to-reach places

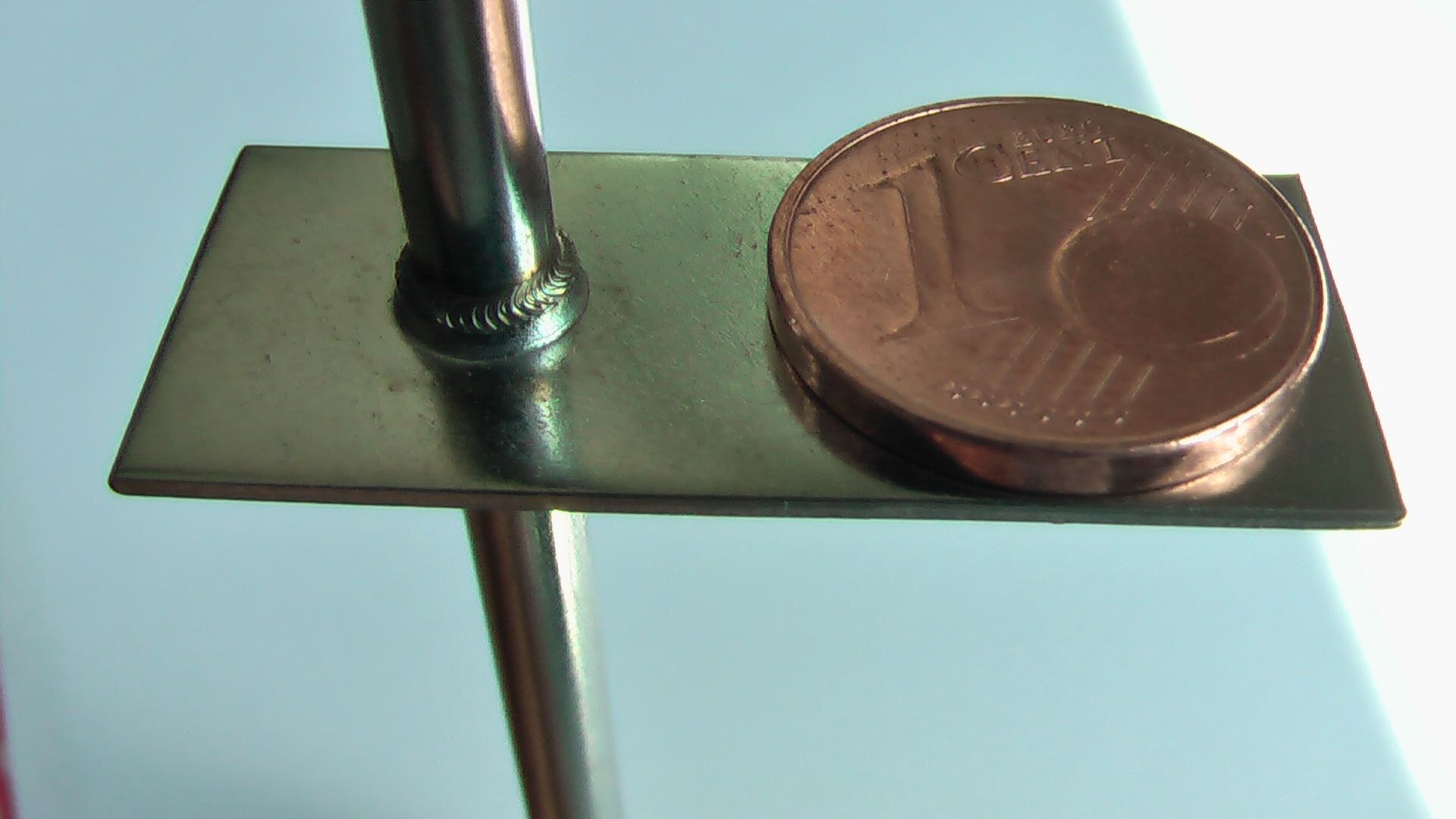

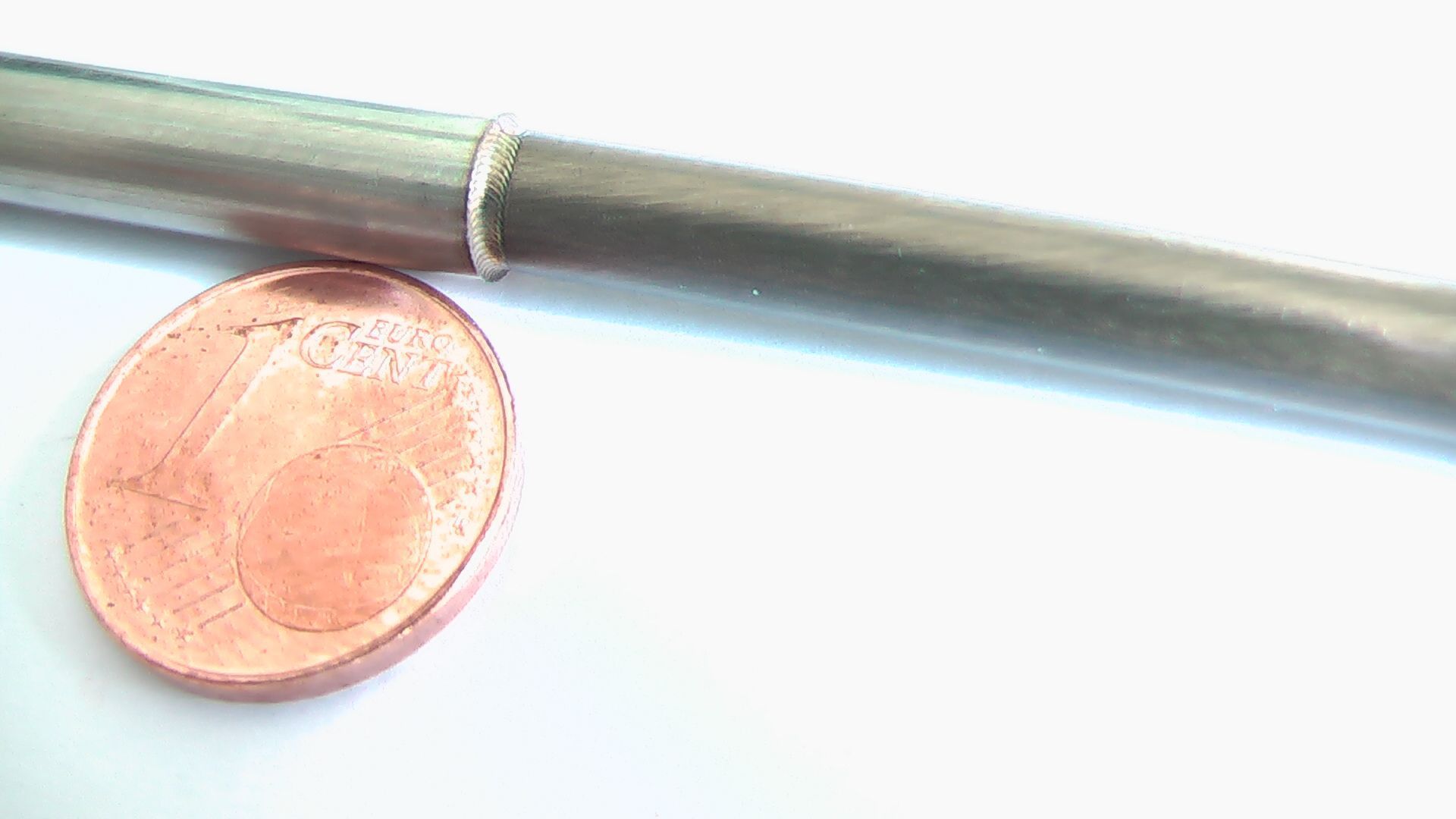

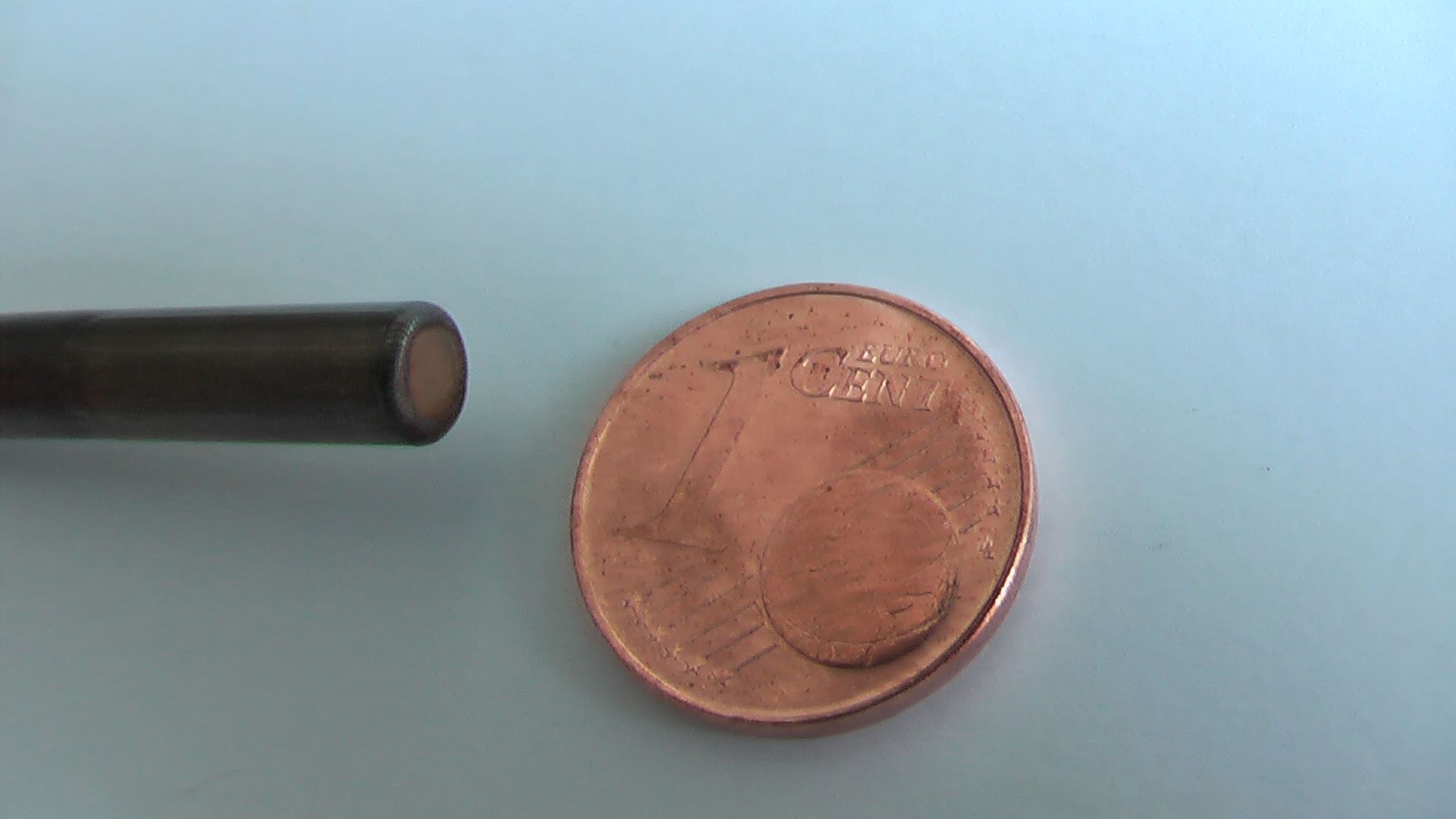

The creation of secure and durable connections between metallic components poses a particular challenge, especially when these are located in hard-to-reach areas. Thanks to our expertise in micro-welding technology and laser welding, we can achieve weld seam depths ranging from 50 µm to 2 mm even under difficult conditions.

With micro-welding technology, we enable precise positioning of the weld points under a stereo microscope. This precise connection of metallic components is not only important in precision engineering and medical technology, but is also required in the production of high-quality jewelry and many other applications.

Precise laser welding using micro welding technology

Precise laser welding using micro welding technology

Our extensive expertise in micro-welding technology enables us to precisely laser-weld a variety of metals. We do not only weld steel and stainless steel, but also:

We take on custom manufacturing as well as series productions and the production of prototypes. We also utilize micro-welding technology for hard-to-reach repair sites. In a personal conversation, we would be happy to inform you about the various possibilities that laser welding offers.

Gold

Silver

Titan

Shape-memory alloys

Experience the advantages of micro welding technology

Are you interested in micro-welding technology and want to know how we use it to achieve excellent results even under challenging conditions? Visit us in Meerbusch and let us demonstrate the numerous advantages of laser welding. Many international companies already trust our work – see for yourself!

Contact us by phone or email to schedule a personal information appointment. We are happy to take the time to answer your questions about micro-welding technology in detail. Benefit from our many years of experience and state-of-the-art technology, and discover what is possible.